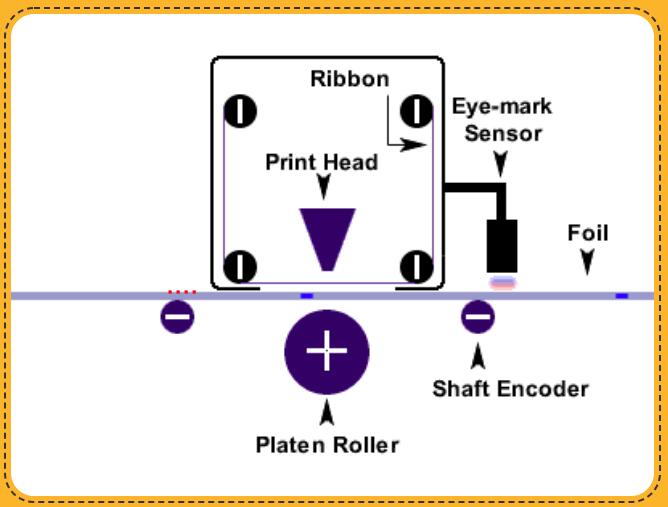

Ukuphrinta kokudlulisa ukushisakuyinqubo, njengesixhumanisi esibalulekile kuyo yonke inqubo yokunyathelisa, ihlobene eduze nezinye izixhumanisi, indlela yokulawula ukuzinza kwenqubo iyisiqinisekiso esibalulekile sekhwalithi yokunyathelisa. Ngezansi, ake sibheke izinto ezibalulekile ezithinta inqubo yokuphrinta yokudlulisa ukushisa.

1. Ikhanda lokuphrinta elishisayo

Iukushisa ukuphrintaikhanda ngokuyinhloko liqukethe ungqimba oluvikelayo lwefilimu engaphezulu, isendlalelo esingaphansi sokuzivikela sefilimu kanye nezinto zokushisa.

Isivinini sokuphrinta sokudlulisa ukushisa sincike esikhathini esidingekayo kumugqa ngamunye wombhalo. Ngakho-ke, ikhanda lokudlulisa ukushisa kanye nephepha lokudlulisa kufanele libe nokusebenza okuhle, ukuze ukushisa okukhiqizwa yisici sokushisa kungadlula ngokushesha ungqimba oluvikelayo, ukudlulisa i-substrate yephepha kanye negebe ekugcineni endaweni ye-substrate, ukuze kuqinisekiswe ukuthi uyinki unayo. isikhathi sokudlulisa esanele.

2. Uyinki

Ukwakheka kukayinki wokunyathelisa wokudlulisa ukushisa ngokuvamile kuba yi-pigment (pigment noma udayi), i-wax namafutha izingxenye ezintathu.

Lapho unyathelisa, i-viscosity yeyinki ehlukene ihlobene ngokuqondile nokushisa okushisa, futhi izinga lokushisa lokushisa kufanele lilawulwe ngokuqinile nge-viscosity ye-inki.

3. Dlulisa iphepha

Ukusebenza okuhle kokushisa ngenxa yesipiliyoni sokudlulisa kufanele kuqedwe ngokusebenzisa izinga lokushisa eliphezulu, ngakho-ke izinto zephepha lokudlulisa kumele zikwazi ukumelana nomthelela wokushisa kokudlulisa, izakhiwo eziqhubekayo zingashintshiwe. Ngokuvamile, ukusebenza okushisayo kwezinto eziyisisekelo zephepha lokudlulisa okushisayo, okungaboniswa yizici ezilandelayo:

a. Ukumelana nokushisa okuphansi nokuncane kwe-substrate, kungcono ukusebenza kokudlulisa ukushisa.

b. Ukushelela kwe-substrate surface, kungcono ukusebenza kwe-thermal.

c. Izinga lokushisa elishisayo lokumelana nokushisa licishe libe ngu-300 ℃, izinto eziyisisekelo kufanele zikwazi ukuqinisekisa ukuthi ukusebenza okuyinhloko akushintshi kulokhu kushisa.

4. Ama-substratesphezulu

Okuhlangenwe nakho kubonisa ukuthi i-substrates yendawo encane eqinile kukhwalithi yokuphrinta yinhle, lokhu kuyisici esisobala sokudlulisa ukushisa. Ngenxa yokuthi indawo engaphansi kwe-substrate ibonisa ukuthi i-substrate inamandla amakhulu, uyinki ephepheni lokudlulisa ungadluliswa kahle kakhulu ku-substrate, uma kuqhathaniswa nezinga elifanele nokuhleleka; Kodwa kabi kakhulu kuzothinta ukudluliswa kweyinki evamile, akusizi ekuqedeni inqubo yokunyathelisa.

Clikc isixhumanisi ngezansi, ungathola abaqeqeshiweamalebula okudlulisa ukushisaudinga.

https://www.colorpglobal.com/heat-transfer-labels-product/

Isikhathi sokuthumela: Jun-20-2022